In northern Vietnam, implementing a closed-loop circular farming model is strongly influenced by climate conditions, high livestock density, and increasing environmental pressure. Prolonged hot and humid weather, cold winter spells, and large temperature fluctuations throughout the year make microclimate control, waste treatment, and odor management significantly more complex than in many other regions. In addition, fragmented land availability and dense residential areas around farms require strict control of wastewater, emissions, and biosecurity.

In this context, a closed-loop circular model in northern Vietnam cannot be treated as a symbolic or purely “green” solution. For large-scale projects, it is fundamentally an infrastructure investment aimed at long-term risk control, including disease outbreaks, rising waste treatment costs, and potential environmental conflicts with surrounding communities. When properly structured, circular systems have a direct impact on livestock performance, operating costs, and the farm’s ability to expand under increasingly stringent regulations.

Closed-loop circularity as an infrastructure and operational management issue

At an industrial scale, a closed-loop circular farm is built on the integrated organization of core infrastructure systems, including waste collection and treatment, wastewater and air emission control, and energy distribution. These systems must be planned from the outset in close alignment with housing design, stocking density, and specific farming methods. Only when material and energy flows are intentionally controlled and linked in daily operations does a true circular system exist.

For large-scale poultry and pig farms, the circular loop typically begins with stabilizing the housing environment and ensuring biosecurity. Waste collection and treatment systems, ventilation, and emission control form the essential foundation for reducing disease pressure and odor. Once these systems operate reliably and provide sufficient control margins, solutions such as heat recovery, treated water reuse, or auxiliary energy utilization can be implemented effectively and sustainably.

Circular farming is therefore not a collection of isolated technical solutions, but an integral part of the overall operations management system. Continuous monitoring of environmental and herd data creates the foundation for applying AI and IoT, enabling better control of FCR, reduced livestock losses, and proactive disease risk management over the long term.

Stabilizing the farming environment under Northern Vietnam’s climate conditions

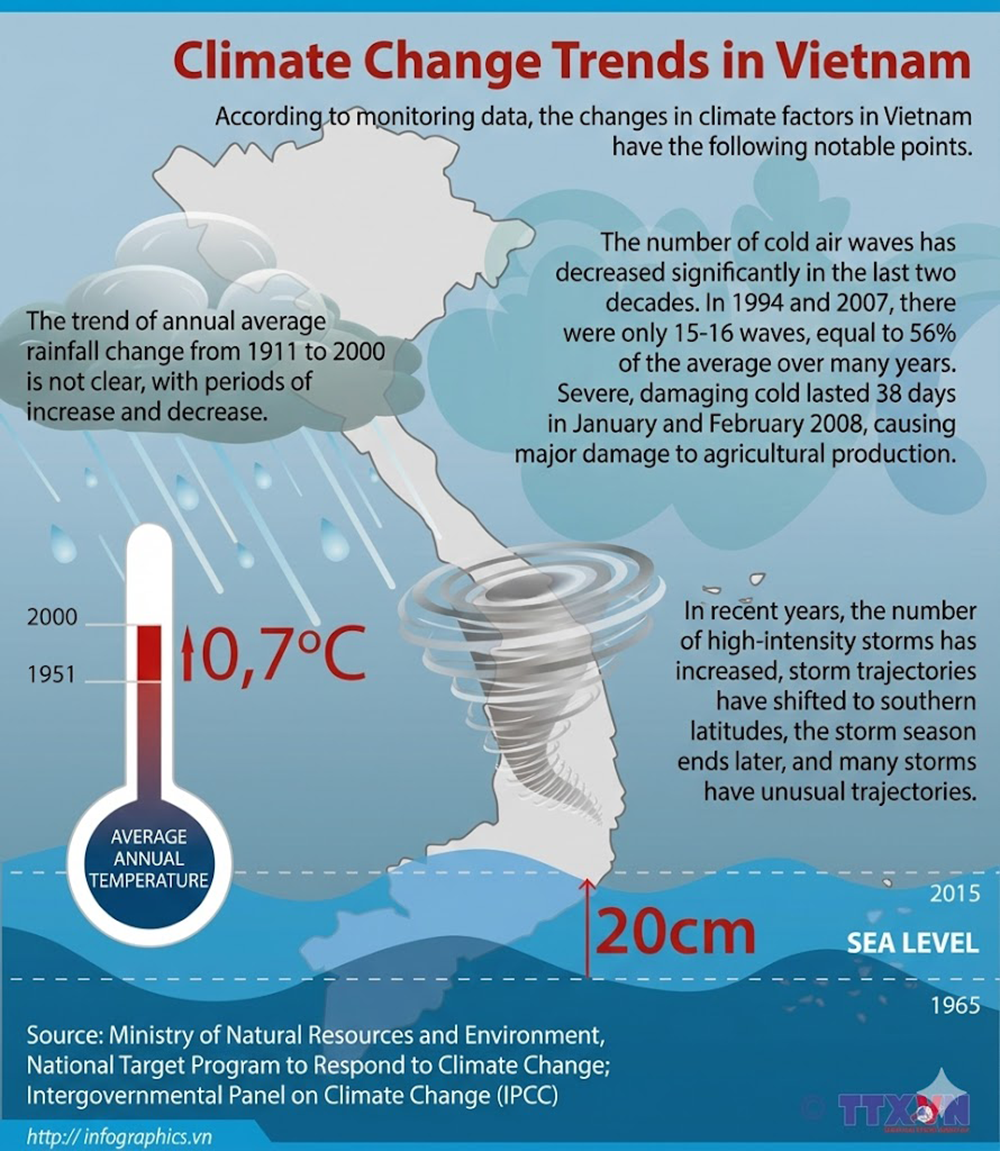

Northern Vietnam experiences strong seasonal fluctuations in temperature and humidity, with long periods of hot, humid summers and occasional severe cold spells in winter. For this reason, large-scale high-tech livestock farms need to invest in appropriate infrastructure and equipment solutions to maintain a stable rearing environment, ensuring animal health and proper growth performance.

Vietnam is heavily affected by climate change, causing significant losses to agricultural production.

Within a closed-loop circular farming model, HVAC systems and microclimate control are integrated to maintain stable temperature, humidity, and air quality inside livestock houses. When the rearing environment remains stable and avoids sharp fluctuations, animals maintain better physiological balance, helping optimize FCR and reduce losses caused by heat stress during extreme weather periods.

Circular systems and long-term financial efficiency

The financial value of a closed-loop circular model does not lie in how much waste it can process, but in its ability to control and stabilize operating costs over time. When water, air, and heat flows are properly organized, the system helps reduce environmental treatment costs, improve energy efficiency, and limit infrastructure degradation under high humidity and corrosive conditions.

These benefits do not generate immediate cash flow, but they have a clear impact on the total cost of ownership over a 10–15 year operating cycle by lowering OPEX, extending equipment service life, and reducing unplanned replacement investments. For large-scale investors, this is an efficiency that only becomes visible when the model is assessed through a long-term financial lens, rather than by comparing initial capital expenditure alone.

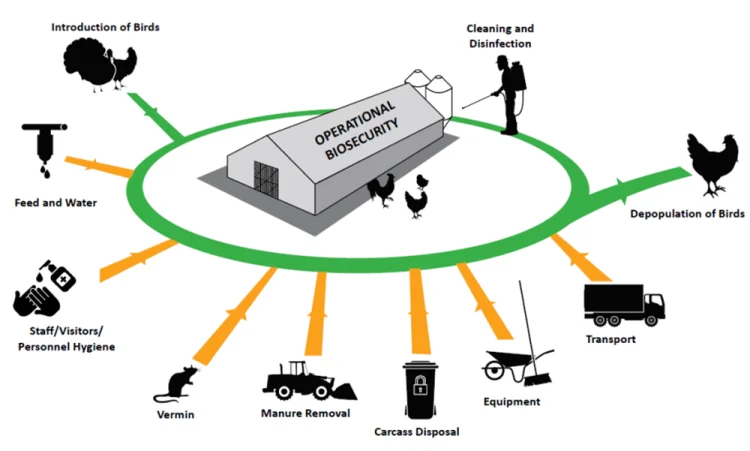

Biosecurity as the foundation of every circular farm

In large-scale closed-loop farms, biosecurity is a core requirement for the circular system to function. Circular infrastructure must be designed based on one-way flow principles, in which all material flows—such as manure, wastewater, and exhaust—are collected and treated entirely separately from the livestock area.

In high-tech circular farms, when these flows intersect, the risk does not stay within the treatment system but reaches the livestock directly. On a large scale, even minor deviations in flow organization can cause significant damage after just a few production cycles.

Digital operation and centralized control

In large-scale farms or farm networks, operational capacity cannot rely solely on on-site responses. A modern circular system must allow centralized data management and remote monitoring to control risks across the entire operation.

When indicators such as NH₃ and H₂S concentrations, temperature, humidity, and waste treatment system performance are collected and displayed centrally, investors can monitor farm conditions from a control center, rather than waiting for issues to occur. This digitalization shifts the farm from passive reaction to proactive management—especially important when operating multiple facilities simultaneously.

Modular infrastructure and controlled scalability

For large investment projects, closed-loop systems should not be designed as rigid, fixed installations. Effective infrastructure is often organized in modular formats, allowing livestock scale-up without dismantling or disrupting existing systems.

This approach preserves investment continuity. As farm capacity increases from initial phases to later stages, circular systems can be scaled according to actual load demand instead of becoming operational bottlenecks or cost burdens.

DELCO Farm’s smart closed poultry housing system – Optimization and evolution

In Northern Vietnam, a closed-loop farming model at an industrial scale is fundamentally a decision about infrastructure governance and long-term financial management rather than a single technology choice. When designed to control climate conditions, biosecurity, operational efficiency, and scalability, the model becomes a tool for stabilizing costs and performance over the long term.

By contrast, if implemented merely as an add-on environmental solution, the circular system can quickly become a new source of operational risk.

From a technical and hands-on implementation perspective, DELCO approaches closed-loop farming as a core infrastructure platform for long-term operational management, designed to control risks, maintain system stability, and support controlled expansion rather than as an idealized model applied uniformly across projects.

See also: High-tech farm models suited to land and climate conditions in Northern Vietnam

See also: High-tech farming solutions by DELCO

See also: Delco Farm: All farming operations managed automatically via software